Introducing Load Star

At U.S. Rubber, we are proud to produce the finest custom belt specification we call Load Star. Our specialty belts are unique to every function and environment they are built for. From the fibers and materials used, to the individual layers in the belt, to the final utilization, our Load Star is an one of a kind that is capable of completing any heavy duty task that comes its way.

Poly/ Nylon Combination

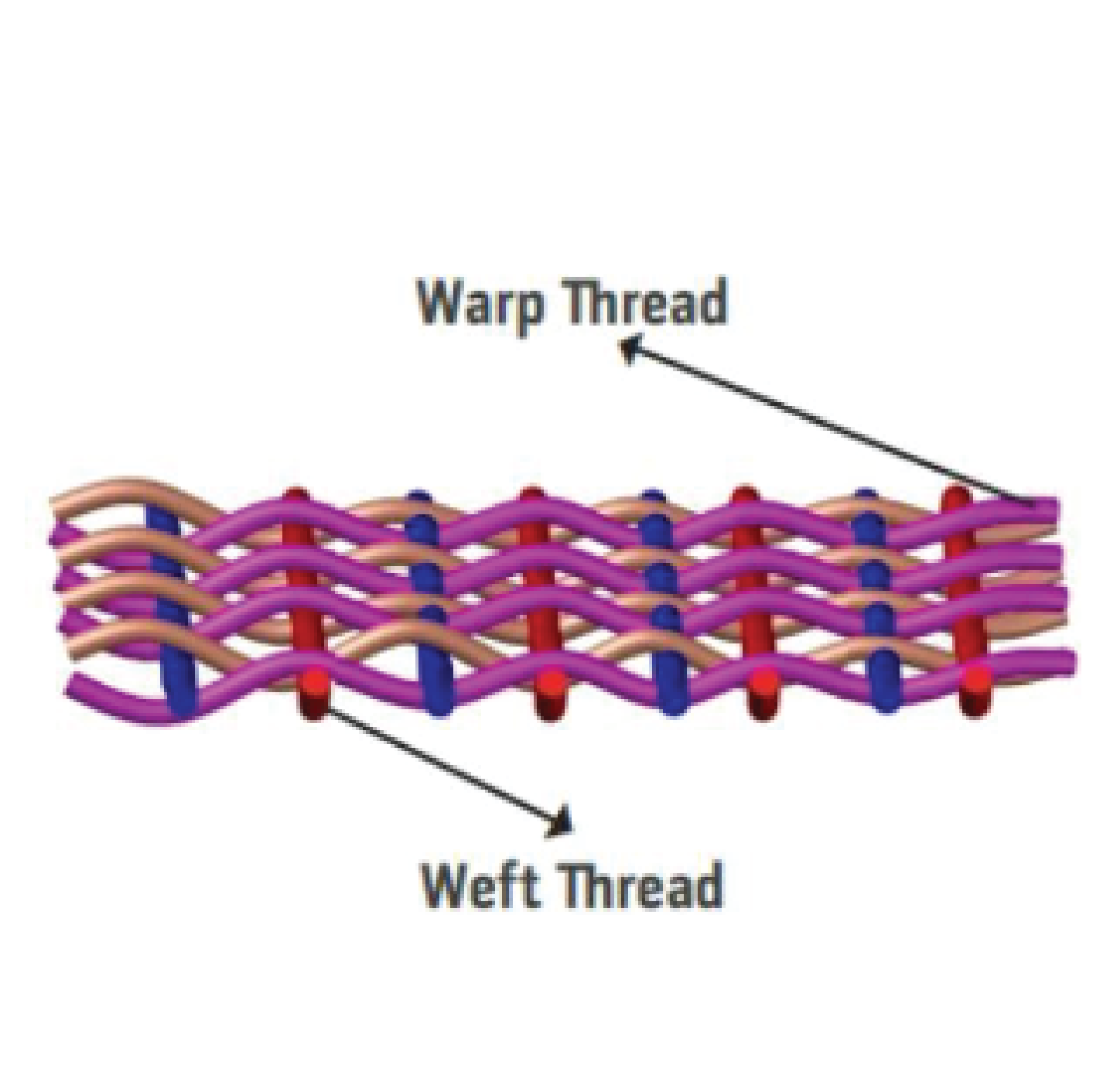

Poly/Nylon -Polyester warp (tensile) yarns and nylon weft or crosswise yarns are utilized as the standard yarns in all stock belt carcass constructions at U.S. Rubber

By utilizing a combination of Polyester and Nylon in its carcass construction, this allows every U.S. Rubber belt to maximize the features for top performance. Polyester warp yarns yield lower elongation, provide greater adhesion in wet applications and secure a stable base to build a quality belting product. Nylon weft yarns yield better fastener holding capabilities, improved troughability and assist in impact resistance.

Plain Weave Fabric

Polyester was selected for the warp or tensile member of the carcass due to high-modulus, low elongation features that reduce belt stretch and provide a more stable base. This stability allows for minimum take up lengths and eliminates the necessity of "breaking in" a belt prior to installing a vulcanized splice. It also eliminates the reinstallation of splices to eliminate start-up elongation and the resultant down time. Polyester also does not absorb as much moisture as other carcass materials, providing higher wet adhesions and a higher percentage of dry-tensile strength where the belt must operate in extremely wet or submerged conditions.

The lower modulus of Nylon allows more elongation; making it the ideal material for the weft or crosswise yarns in a belt carcass. The higher stretch allows the belt to trough under a lighter load than high-modulus polyester, resulting in better tracking characteristics. The elongation also provides shock absorption that yields higher fastener retention and higher longitudinal tear resistance.

Load Star Construction

Utilizing 110, 125, 150, 200, 250, 300 and 400 pound per ply PIW, 10:1 Service Factor fabrics, U.S. Rubber is capable of producing Heavy-Duty fabric-plied belt specifications from 2 ply 220 pound PIW working tension up to 4 ply 1600 pound PIW working tension.

Top Cover:

Any thickness from 1/32" to 1 1/2"

Carcass:

1 to 10 plies

Skims:

Heavy and high adhesion skim

Bottom Cover:

Any thickness from 1/32" to 1"

Bare back also available (0.8-25.4mm)

F E A T U R E S

Load Star Advantages

High Safety Threshold

Full 10:1 service factory Poly/ Nylon carcass

Low Elongation

Less than 2% at 100% working tension

Moisture Tolerance

Premium "wet" application strength

Superior Adhesion

Premium fastener holding capabilities

Meets Testing Requirements

Passes MSHA, ASTM, and ISO regulations

Reliability

Excellent troughability

Our Promise To You

Premium Quality

Product

Custom Orders

To Spec

Competitive

Leadtime

Outstanding

Customer Service

Interested In Our Product?

We want to know your needs exactly so that we can provide the perfect solution. Let us know what you want and we’ll do our best to help.